1 Overview

The RQD-D7 magnetic soft starter is standard product, which is also innovative, cost-effective, and conducive to flexibility of driving system. The first set of magnetic soft starter came out in May, 2002. It showed that this product doesn't exist in foreign market according to novelty-checking and retrieving. It is evolved from the electric reactor starter. Both of them connect reactor to motor stator so as to achieve voltage drop. The difference is that the magnetic soft starter works by replacing the fixed reactor with controllable saturable reactor. Once starts, the saturable reactor will be bypassed.

In the magnetic soft starter, it is the SCR that controls the motor current by resorting to amplification of power and voltage of the controllable saturable reactor, which is different from in the thyristor soft starter. The saturable reactor takes responsibility of withstanding high voltage and large current. The magnetic soft starter has advantage of reliability, low cost and environment friendly.

2 RQD-D7 type magnetron soft start device

2.1 principles:

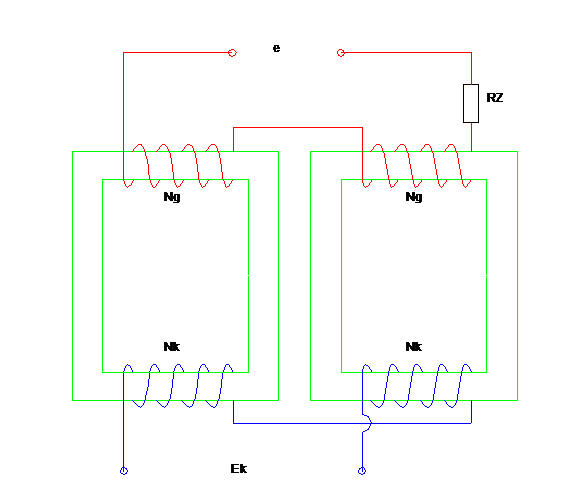

The operational winding of the saturated reactor is connected in series to the stator loop of the motor. The DC current magnitude of the reactor control winding is regulated through the feedbacks of the stator current so that to change the saturation of the saturated reactor and achieve soft start. Its regulation principle is the same as the thyristor soft starter.

2.2 composition

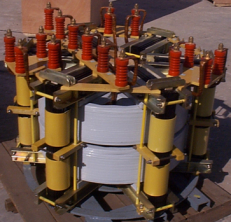

Saturated reactor: It consists of iron core and winding. The winding is divided into AC winding (working winding) and DC winding (controlling winding).

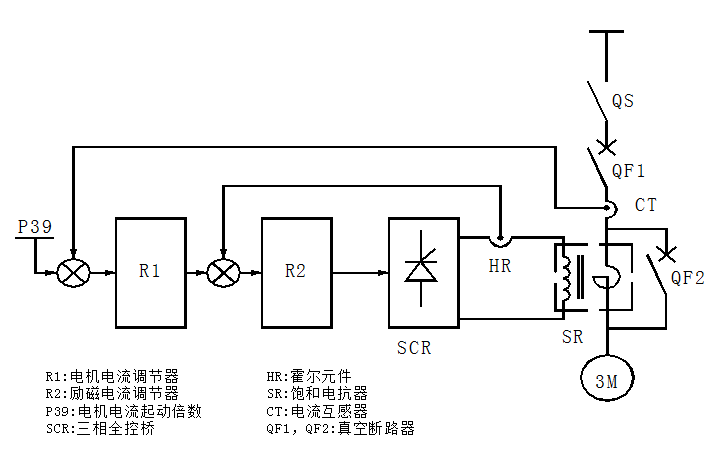

Control unit: The main circuit consists of 3-phase fully controlled bridge rectifier circuits, and the regulator is composed of Siemens PLC S7-224 and the pulse amplifiers produced by XDE. Siemens TD200 HMI is employed as display to show and set parameters as well as to check the incidents and starting wave.

2.3 starting characteristics:

Initial voltage (Initial current): It determines the initial starting torque of the motor (torque is proportional to square of the operating voltage) and could be set according to the load torque requirement. The general setting range: 30-70% of rated voltage.Constant value of soft start current: 150-450% of the rated current of motor. Starting time: Determined by motor and load moment of inertia, generally 20-40 seconds.

2.4 data needed for design:

2.4 data needed for design:

Motor parameters: motor power (KW), motor rated voltage (V), motor rated current (A), motor rated speed and maximum torque of /Me, torque /Me, torque current /Ie, motor inertia GD2; power parameter: minimum short-circuit capacity of the power grid (MVA) or minimum short-circuit current value (KA), the voltage fluctuation range (%); load parameters: load (fan, compressor, water pump), load inertia GD2, converted to the motor shaft static friction torque transmission, increasing (decreasing) ratio of K.

2.5 scope of application:

Squirrel cage asynchronous motor, Synchronous motor, Drag load type: Pump, (such as water supply, sewage treatment), Blower and fan, Compressor, Ball mill, Rolling mill and Belt conveyor etc.

A saturable reactor is a cored AC circuit with additional DC excitation, or reactor with DC excitation. By means of the magnetic saturation , the DC excitation is used to change the working point and magnetic characteristics of the magnetic state of the core, thereby changing the reactance of the AC winding. This component is called a magnetron saturation reactor, or a saturated reactor.

When the DC exciting current is zero, it is equivalent to the no-load state of the transformer. When the DC exciting current is constant, the magnetic induction in the iron has both DC component and AC component. The accumulative effect of AC and DC excitation, the core work on magnetic properties of saturation, so the AC magnetic field strength increases, the equivalent permeability core decline.

SR part: the AC winding of the saturable reactor SR has a strong current limiting effect when the DC excitation is zero, because of the magnetization of silicon steel sheet (that is, the magnetization curve of silicon steel sheet). The DC exciting current gives the curve a certain bias so that the curve enters the saturation zone more, weakening the current limiting action of the AC winding.

PLC part: the PLC section includes the SIEMENS S7-224 module, the power amplifier board and the thyristor rectifier bridge. Magnetron soft start device comparison motor setting current and current deviation detection, the set value by the motor current regulator R1 gives the excitation current, which was compared with the actual excitation current from the Holzer element, by the excitation current regulator R2 according to the principle of negative feedback control of three-phase full bridge controlled rectifier circuit SCR trigger angle, closed loop current control. The above R1, R2 regulation and SCR trigger are all performed by PLC. In the device, PLC is also in charge of comprehensive protection and communication etc..

4 electrical schematic

5 The technical features

5.1This device conducts constant current start by controlling the motor control, thus minimizing the impact on the power grid and machinery in the starting course. The starting current can be regulated between the range of 1.5le-4.5le (decided by different load), with no need of secondary current surge after starting.

5.2 Overheat protection on motor and starter.

5.3 The whole starting process can be predicted, controlled and adjusted with the computer simulation technology.

5.4 The starting curve can be optimized by parameter setting; motor starting ratio can be set continuously. Operating parameters are stored in the EEPROM.

5.5 This device employs the Siemens PLC and advanced multi-function modules, featuring simple structure, reliable performance, flexible setting etc,.

5. 6It is equipped with standard HMI interface, on which running state and relevant data are shown in two lines. 8 function keys and 5 setting keys are responsible for parameter setting, display, system controlling and on-line guidance(in Chinese)etc,.

5.7,t is provided with self-diagnosis function for intelligent detection of machine breakdown, such as abnormal voltage, phase loss, phase sequence faults etc,.Once error detected, the device can be blocked automatically.

5.8 Incident logging function keeps the record of the last 50 incidents with exact times and stores the starting wave. Starting data can be shown on text display. Starting wave can be checked on computer..

5.9 It enjoys superior repeatability of soft starting, with performance free from influence of ambient temperature.

5.10 Long service lifespan and maintenance-free.

5.11 It can realize soft stopping.

6 technical data

Power device | Saturable reactor |

Control device | S7-200 PLC |

System voltage | 0.38kV, 6 kV, 10 kV |

system voltage | 0.38kV,6 kV,10 kV |

Auxi. power supply | 0.38kV |

Motor power | 100 kW---50000 kW |

Starting current multiple | 1.5le~4.5le |

Maximum starting time | 60-100sec> |

Number of consecutive starts | 3-5 times |

Magnetic leakage | No leakage, no influence on other equipment |

ambient temperature | 0-40℃,Max.60℃; Derating if above 40℃ |

Installation height | The altitude is not more than 1000m. Over time, altitude, volume and capacity shall be used。 |

Maximum relative humidity | 95%,non-condensing。 |

Protection level | IP32 |

Cooling method | Natural air cooling |

7Reference standard

GB/T3906-1991 <-35KV AC metal enclosed switchgear>

GB/T3797-1989

GB191-2000

GB4208-1993

GB/T14549-1993

Q/12QT3950-2002

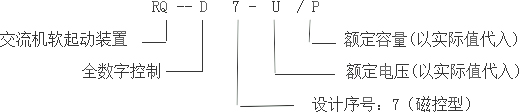

8Product model

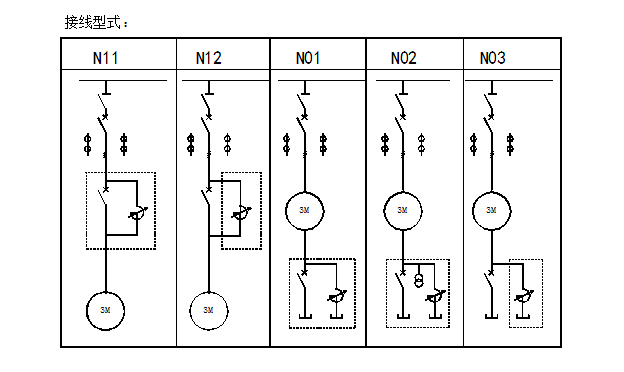

9.Connection type

Wiring type according to AC start refers to the following figures

N11: Device is connected to the power side of motor;

N12: Device is connected to the power side of motor without shorting switch;

N01: Device is connected to the neutral point of motor;

N02: Device is connected to the neutral point of motor with additional mutual inductor to measure the starting voltage;

N03: Device is connected to the neutral point of motor without shorting switch;.

10Type selection and order data

Model | Rated voltage(kv) | Rated power (kw) | Outline size(mm)(WxDxH) | Connection type | Control power supply |

RQD-D7-0.38 | 0.38 | ≤100 | 800x800x2200 | N11 | 3AC380V20A |

| ≤200 | 800x800x2200 | N11 | 3AC380V30A |

| ≤280 | 800x800x2200 | N11 | 3AC380V40A |

| ≤355 | 800x800x2200 | N11 | 3AC380V40A |

RQD-D7-6 | 6 | ≤250 | 1000x1000x2200 | N01-03,N11-12 | 3AC380V20A |

| ≤400 | 1200x1200x2200 |

| 3AC380V30A |

| ≤630 | 1400x1400x2200 | N01-03,N11-12 | 3AC380V60A |

| ≤1000 | 1400x1400x2200 |

| 3AC380V120A |

| ≤2000 | 1500x1500x2200 | N01-03,N11-12 | 3AC380V180A |

| ≤3200 | 1600x1600x2200 |

| 3AC380V200A |

| ≤5500 | 1600x1600x2200 | N01-03,N11-12 | 3AC380V300A |

| ≤6300 | 1600x1600x2200 |

| 3AC380V315A |

| ≤8000 | 1600x1600x2200 | N03,N12 | 3AC380V380A |

| >8000 | According to actual conditions | N03,N12 | According to actual conditions |

RQD-D7-10 | 10 | ≤250 | 1000x1000x2200 | N01-03,N11-12 | 3AC380V20A |

| ≤400 | 1200x1200x2200 |

| 3AC380V30A |

| ≤630 | 1400x1400x2200 | N01-03,N11-12 | 3AC380V60A |

| ≤1000 | 1400x1400x2200 |

| 3AC380V120A |

| ≤2000 | 1500x1500x2200 | N01-03,N11-12 | 3AC380V150A |

| ≤3200 | 1600x1600x2200 |

| 3AC380V215A |

| ≤4500 | 1600x1600x2200 | N01-03,N11-12 | 3AC380V260A |

| ≤6300 | 1600x1600x2200 |

| 3AC380V330A |

| ≤8000 | 1700x1700x2200 | N03,N12 | 3AC380V350A |

| >8000 | According to actual conditions | N03,N12 | According to actual conditions |

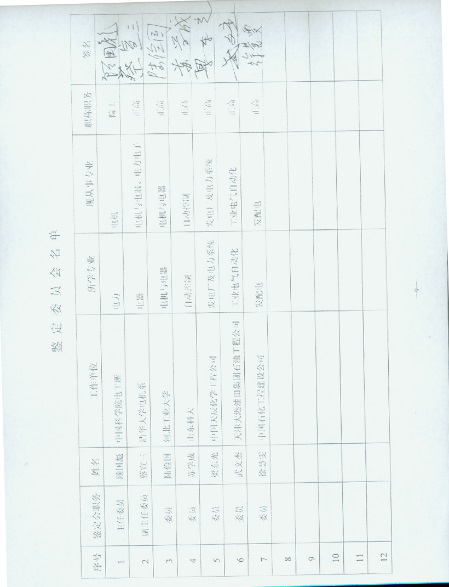

11 Identification Report

The high voltage magnetic soft starter is firstly developed by XDE In 2001, and applied to the 2000KW blast furnace blower of Jiyuan Steel in Heinan Province in May, 2002. It was proven by the authorities that there was no other similar products available in Chinese market in that period. The product has been acknowledged by academicians, experts and scholars of Tianjin Science and Technology Committee. The whole process of design, production and delivery of RQD-D7 Magnetic Soft Starter has been identified by the GB/T19001-2001 standard.

12 application case

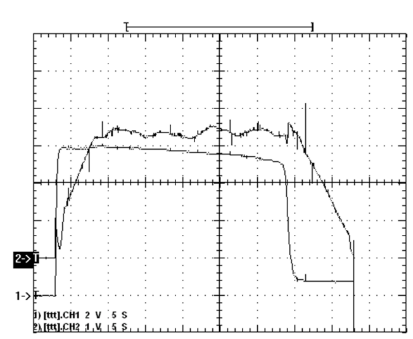

Application 1: The application of the magnetic soft start in the air compressor of the oxygen plant of Jiyuan Steel Plant, the soft start current is selected as 1850A (3.3 times of the rated current value of the motor), and the soft start completion time is 32 seconds.

Application 1: The application of the magnetic soft start in the air compressor of the oxygen plant of Jiyuan Steel Plant, the soft start current is selected as 1850A (3.3 times of the rated current value of the motor), and the soft start completion time is 32 seconds.

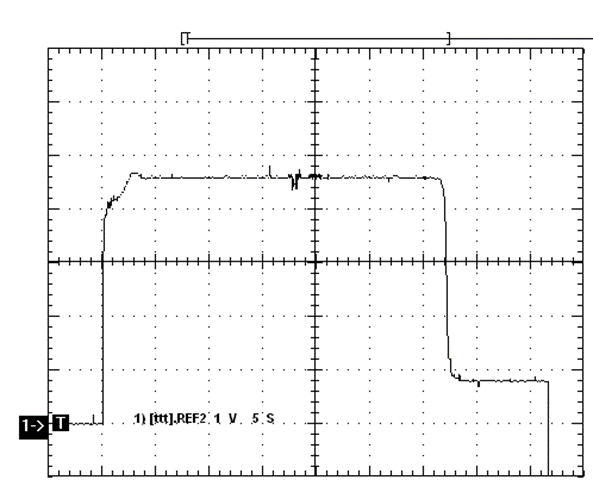

The application of magnetic soft start in Jinhua Petrochemical, 2# pump load motor starting curve, P=3150KW, U=6KV, I=354A, N=2985rpm, 3.5 times current, start for 32 seconds. Commissioning time.

The application of magnetic soft start in Jinhua Petrochemical, 2# pump load motor starting curve, P=3150KW, U=6KV, I=354A, N=2985rpm, 3.5 times current, start for 32 seconds. Commissioning time.

![]()